【PTFE】球墨法兰四氟橡胶接头“适用于航空煤油”

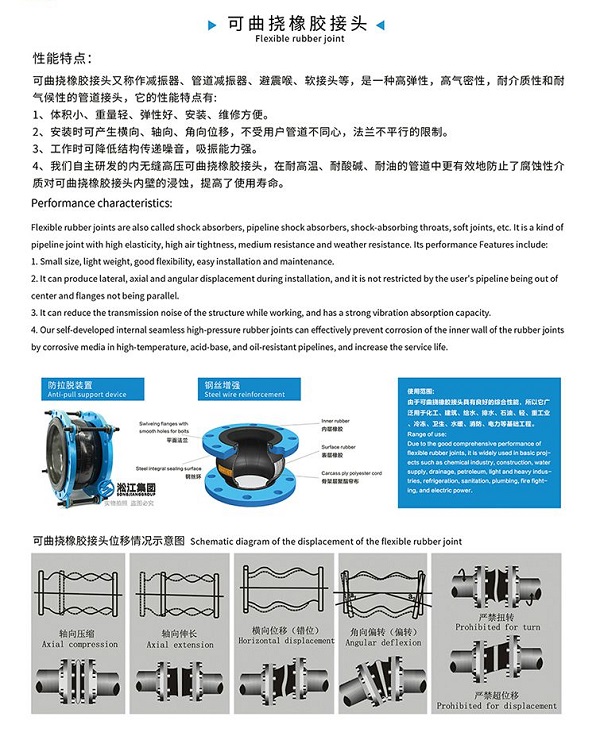

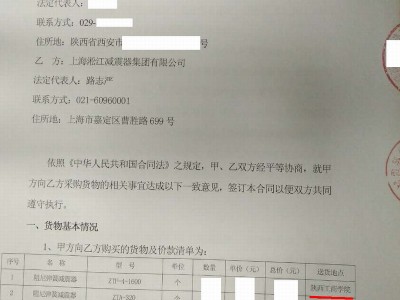

上海淞江减震器集团有限公司网站为您介绍:【PTFE】球墨法兰四氟橡胶接头“适用于航空煤油”信息,淞江集团为众多客户提供四氟橡胶接头,该产品主要适用于航空煤油管道,内衬一层聚四氟乙烯材料,具有良好的耐航空煤油性能,在我厂的案例中具有良好的使用案例。

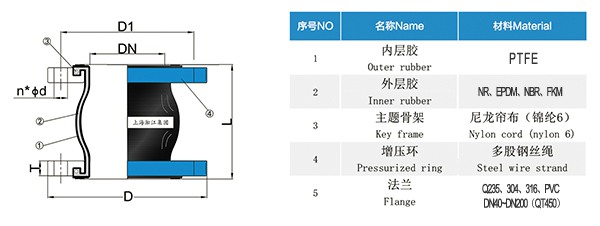

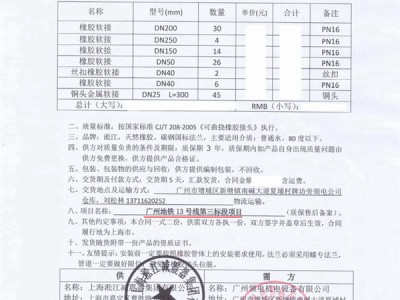

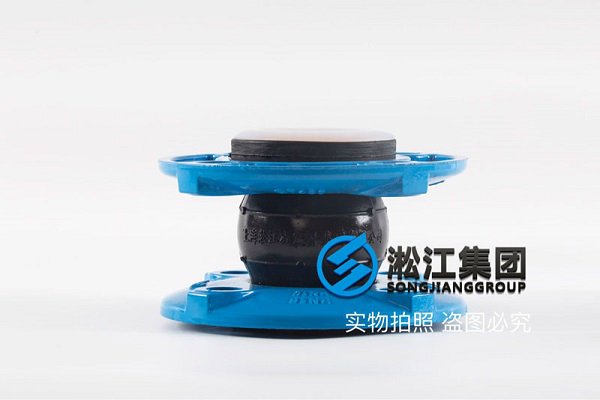

名称:球墨法兰四氟橡胶接头

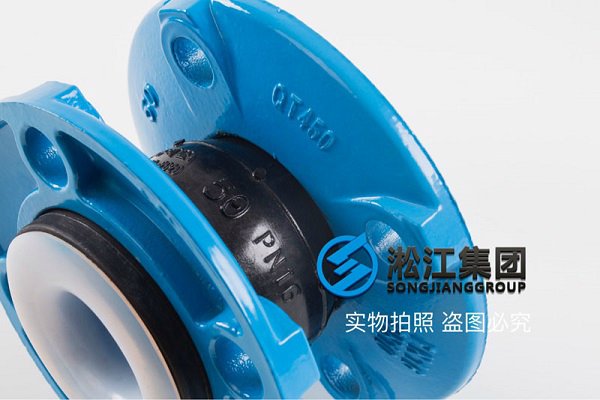

法兰:球墨QT450

橡胶:天然橡胶

内衬:聚四氟乙烯

口径:DN40~DN200

压力:PN10~PN16

介质:航空煤油、汽油、柴油、乳化液。

温度:80度以下

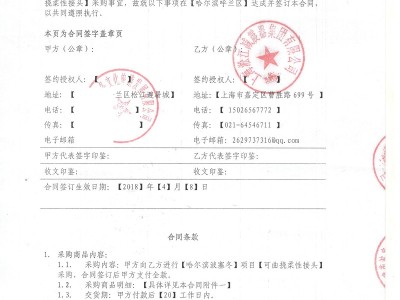

货期:10天

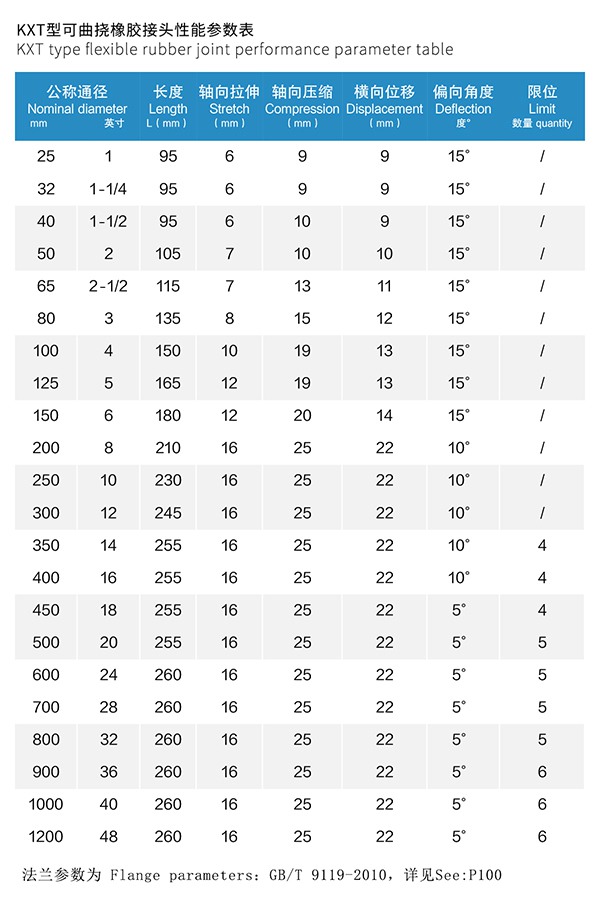

NR:80度以下,普通水、生活污水、空调循环水、河水、冷却水、消防水、饮用水、空气、压缩空气;

NBR:液压油、乳化液、润滑油、稀油、石油开采;

NBR-TS:汽油、柴油、航空煤油;

EPDM:120度以下,热水、弱酸,强碱,海水、食品、饮料、天然气、电厂石灰浆液、电厂脱硫、石灰石、太阳能热水、地源热泵、锂电酸碱管线、汽车喷涂、汽车电泳、废水污水、垃圾渗滤液;

内衬PTFE:温度80度以下,强酸碱、航空煤油、石油、柴油、汽油,(非负压真空);

FKM:耐酸碱、耐油、耐高温、通用性强,价格高;